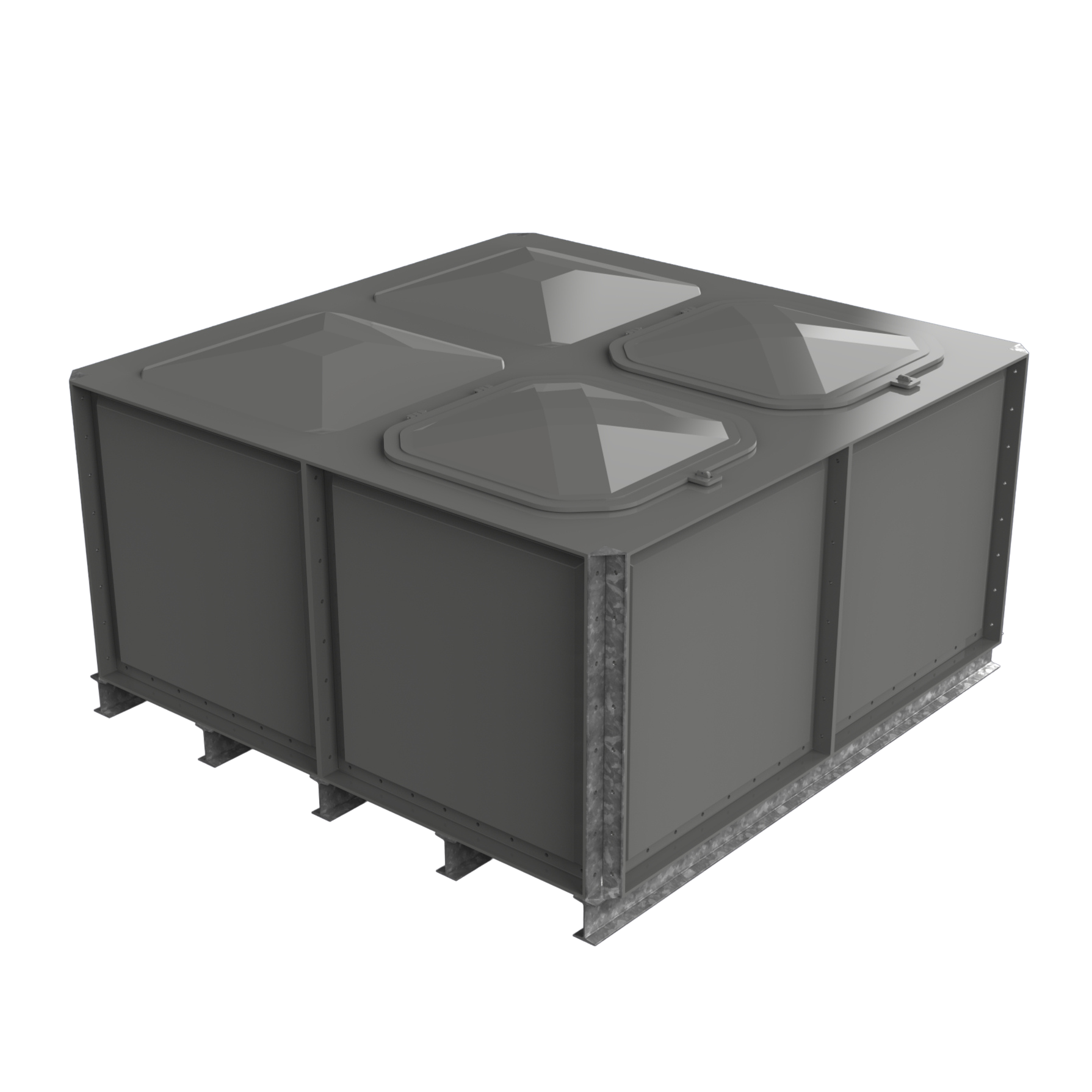

Sectional GRP Tanks

The GRP Sectional Hot Press Moulded Tanks are modular water storage solutions designed for large-capacity applications, ranging from 125 litres to 2 million litres. Manufactured using hot press moulded GRP panels, they ensure maximum dimensional stability, durability, and compliance with WRAS and BS EN 13280:2001 standards. Available in internally flanged (IFB), externally flanged (EFB), and totally internally flanged (TIF) configurations, these tanks provide versatile installation options for sites with access restrictions. With pre-insulated panels, corrosion-resistant components, and a unique bracing system, they offer high performance, easy maintenance, and long-term reliability for potable and non-potable water storage applications.

Key Features:

- Modular Design – Supports storage capacities from 125L to 2 million litres.

- Hot Press Moulded GRP Panels – Ensures dimensional stability and durability.

- Three Configuration Options – IFB, EFB, and TIF for different installation needs.

- Pre-Insulated Panels – Factory-applied CFC-free polyurethane foam insulation for temperature control.

- WRAS & BS EN 13280:2001 Approved – Certified for potable water storage.

- Largest Manway access in the industry – 775 x 845mm aperture for easy maintenance.

- Corrosion-Resistant Fixings & Bracing System – Stainless steel and galvanized components for long-term performance.

- On-Site Assembly by Skilled Engineers – Ensures quality installation and compliance with specifications.

Product Applications:

Domestic

Commercial

Industrial

Hospitality

Specification

Technology: Modular GRP sectional cold water storage tanks

Capacity Range: 125 litres to 2,000,000 litres

Material: Hot press moulded GRP panels

Insulation: Factory pre-insulated with CFC-free PU foam

Base Configurations: Internally flanged (IFB), externally flanged (EFB), totally internally flanged (TIF)

Lid Type: Removable panels with large 775 x 845mm man-way access

Regulatory Compliance:WRAS Approved, BS EN 13280:2001, ISO 9001:2015

Structural Support: Stainless steel or galvanised steel bracing

Installation: On-site assembly by trained engineers

Foundation Requirements: Flat, level, and continuous structural base

Backflow Protection: Raised float valve housing with screened spill-over weir for AB air gap compliance

External Coating: Polyester gel coat for enhanced durability

Bracing System: High-grade flange stiffening bars and box section uprights

Internal Division Options: Optional divider panels for uninterrupted water supply during maintenance

Optional Features: Float valves, screened overflows, level controls, chlorination services

GET IN TOUCH